Cable assembly process depends on the type of fiber optic and its connector type.

We are going to cover the cable preparation for a 900 micron buffered fibers. There are also known as simplex cables generally used in backplane applications, and desktop connection.

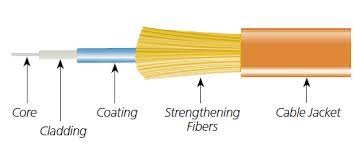

Simplex cables are composed of the outer jacket usually 3mm diameters. Kevlar, which are also known as strength members and the 900-micron buffer over the primary buffer coating.

First, preparing the workspace is a very crucial step, it is better to work on a black surface because it helps to see clearly the fiber.

Open the connector package and slip the cable support the bushing and the crimp sleeve into the outer jacket of the fiber optic.

Strip the outer jacket and the Kevlar, using a fiber stripper. It is important to know what your strip length is going to be and the manufacturer of the connector usually indicates that. What you will be left with is a specific length of buffer and some of the Kevlar to cover the whole post of the connector.

Then remove the protective cladding that surround the field fiber, a heating system can be used to soften the coatings so they can be easily removed.

Cleaning the bare fiber is a crucial step to remove any coating residue, using the alcohol pad or lint-free cloth dampened with isopropyl alcohol. Once cleaned, the fiber must be prevented from any contact with any potentially contaminated surfaces or materials; this is because even a tiny speck of dust can completely block the light, which can result in bad fusion splices and inadequate bonds.

Cleaving is the process of cutting the fiber end flat using a fiber optic cleaver. Cleaving is “a professional cute technique” of the fiber core, as the latter is made of glass a “nonprofessional cute” will broke it, leaving scratches of the surface in order to prevent this, using a special cleaving will cut the glass in a smooth manner. With a properly well-done cleaving, the end of the fiber will have a perfectly smooth right angle.

Inspection: Inspecting BOTH sides of the fiber connection is the ONLY WAY to ensure that it will be free of contamination and defects. Inspecting and cleaning connectors, test ports and reference cords before testing network connectors prevents cross-contamination.

Fiber Optics Testing: Troubleshooting, Verification, and Certification (Fluke tester). Certification of a fiber optic cabling per IEEE, TIA/EIA, or ISO/IEC standards is necessary to ensure that the link will run the intended application.

Contact: Andy Huang

Phone: 0086-755-89239407

E-mail: sales@beskco.com

Add: No.3106,Longgang Avenue,Pidi Town, Longgang District, Shenzhen China

We chat